The touch panel of this machine uses a 4-wire resistive film method (low load resistive film analog 4-wire method). It can detect two points for flick/drag/pinch-in/pinch-out operations. Resistive touch panel has been adopted in order to allow operation with a prosthetic hand.

Basic Structure

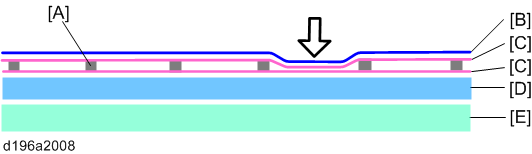

An analog 4-wire resistive film touch panel has 2 layers. Two materials (mainly film or glass) with transparent conductive film (ITO) are attached such that the transparent conductive film layers face each other.

When the film is pressed with a finger or a pen, the transparent conductive films contact each other and the touch panel operation is recognized.

Insulators (spacing dots) secure space between the two transparent conductive film layers to prevent short-circuiting.

Because the transparent conductive film has a uniform resistance characteristic, the resistance value reflects the distance of contact.

[A]: Spacing dot

[B]: PET film

[C]: Transparent conductive film

[D]: Base glass

[E]: LCD panel

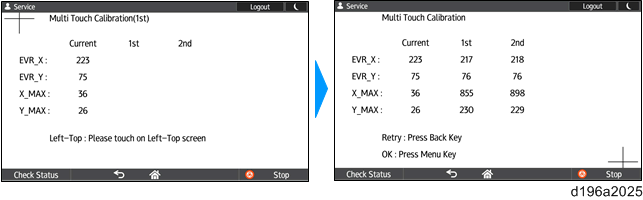

Self-Check (multi-touch calibration) mechanism

With the Multi-touch calibration in the self-check function, the touch panel is automatically calibrated using the results of touches to the top left and bottom right positions.

The values of “EVR_X”, “EVR_Y”, “X_MAX”, and “Y_MAX” are used for internal processing. They do not indicate the positions or distance of the touched points. There is no problem unless there is a huge difference between the values of the first calibration and the second calibration.