Outline

IBACC (Intermediate Belt type of inner ACC) maintains the quality of gradation in the images. To do this, the machine makes a gradation pattern on the transfer belt, and measures variations in density between the middle to the highlight tone, which solid printing control cannot correct perfectly. The machine feeds back variations in the density to the image-processing parameters (the digital gamma correction table).

Operation Timing

IBACC must be done in the shortest time possible, in cooperation with process control. This is because the process requires time to adjust. If the ON/OFF setting of IBACC operation (SP3-600-030) is ON, IBACC is done at the time of normal process control. If the setting is OFF, the IBACC is not done.

Before the IBACC procedure, the machine determines whether IBACC can be done, based on the engine condition. If there is an error in the latest process control, the following IBACC is considered to be unnecessary.

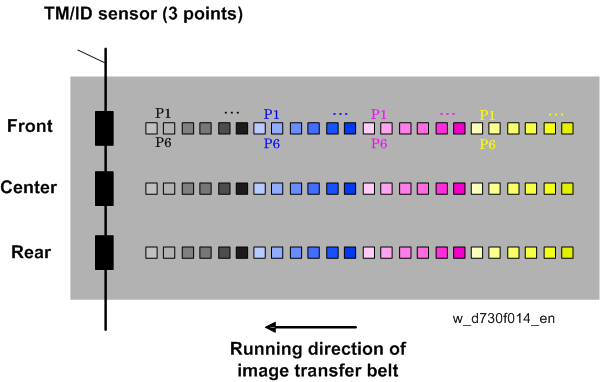

Patch Pattern

16x16 patterns are created. The order of the tones depends on the image processing layout. There are patterns for 600 dpi and 1200 dpi.