IM C6000/C5500/C4500

IM C3500/C3000/C2500/C2000

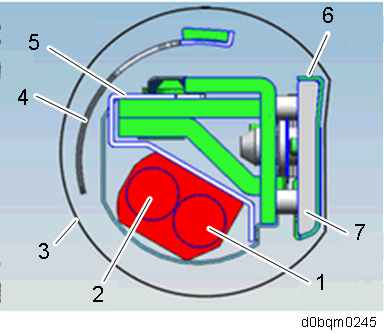

No. | Description | No. | Description |

|---|---|---|---|

1 | Fusing lamp (center) | 5 | Reflector |

2 | Fusing lamp (edge) | 6 | Soaking plate |

3 | Fusing sleeve belt | 7 | Nip pad |

4 | Shield* | - | - |

* IM C6000/C5500/C4500 only.

IM C6000/C5500/C4500: New QSU-DH (Quick Start Up-Direct Heat) fusing

This is a fusing unit with a soaking plate added to the pressure pad on the fusing nip.

In addition to the mechanism to efficiently heat the paper according to its width by rotating the shield plate, a soaking plate to even out the temperature of the fusing sleeve belt in the longitudinal direction is adopted.

It controls the shading position on 9 levels by adjusting the rotating time according to the paper width after turning on the main power switch and after starting/finishing printing.

The soaking plate on the nip (on the surface of the pressure pad) disperses the temperature deviation between the front and rear parts of the fusing sleeve belt, so as to even out the temperature.

IM C3500/C3000/C2500/C2000: E-QSU (Enhanced-Quick Start Up) fusing

This fusing unit has the soaking plate added to the pressure pad on the fusing nip and removed the shield plate control.

The model of 35cpm or below requires a little amount of heat, so it controls the temperature by the soaking plate and heater control at the edges and center.

The soaking plate on the nip (on the surface of the pressure pad) disperses the temperature deviation between the front and rear parts of the fusing sleeve belt, so as to even out the temperature.

A Fusing belt is driven by drag rotation following a pressure roller and presses a nip pad against the pressure roller to fix toner on the paper.

The heater emits light and a point on the left of the fusing belt which is heated moves in an anticlockwise direction so that heat is transmitted up to the contact point with the pressure roller.

Heater

Comprises two parts

The number of watts of heater:

IM C6000/C5500/C4500 | IM C3500/C3000 | IM C2500/C2000 | ||||

|---|---|---|---|---|---|---|

NA/TWN | EU/AA/CHN | NA/TWN | EU/AA/CHN | NA/TWN | EU/AA/CHN | |

Center | 809W | 816W | 809W | 700W | 647W | 700W |

Edge | 430W | 679W | 430W | 527W | 344W | 527W |

Nip pad

Presses against the Pressure roller to form a fusing nip. The top surface is covered with a slippery sheet.

Reflector

Transmits heat efficiently to the left of the fusing belt.

Shield

Shield width changes by rotating the shield according to the paper width. Ensures that light from the heater is not transmitted to the fusing belt edge (prevents excessive edge temperature rise when printing small size paper).

Flanges

Situated on both ends of the fusing belt. They maintain the shape of the belt.

Soaking plate

Disperses a temperature deviation in a longitudinal direction of the fusing belt to uniformize.