The paper feed unit employs an RF system.

In a conventional FRR system, transport of 2 sheets at a time is prevented by reverse rotation of the separation roller, but in the RF system, paper separation is assisted by the resistance of the separation roller with a torque limiter (reverse drive is not performed).

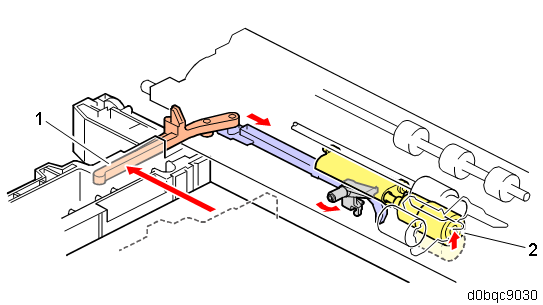

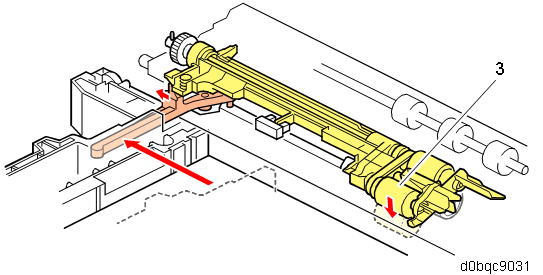

When the paper feed tray is set in the machine, a pressure release lever [1] is pressed, the friction roller [2] comes in contact with the paper feed roller, and the pick-up roller [3] contacts the top of the paper (to prevent paper remaining, when the paper feed tray is withdrawn, the pressure release lever returns and contact with the rollers is released).

The machine is in standby mode for paper feeding when the tray bottom plate moves up. When the paper feed motor (M6) turns ON, the rollers start to rotate and paper is fed.

The feed guide functions as a paper guide and roller clip ring. The feed guide prevents the paper from winding up.