The ID Sensors (also called the TM/ID sensors) are used to measure the amount of toner on the Transfer Belt and to correct any errors in color registration.

The TD sensor (also known as the μ sensor) is used to measure the toner density in the developer.

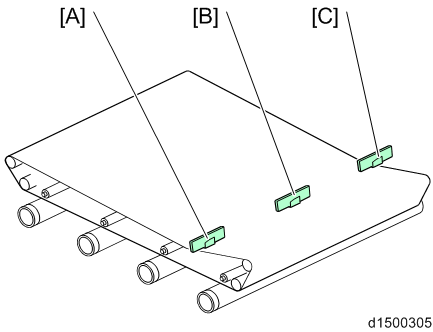

Outline of the ID Sensors

The ID sensors are fixed onto the mainframe, against the surface of the Transfer Belt. Color registration is checked by all three sensors; the Front [A], Center [B], and Rear [C].

The center sensor [B] acts as an ID sensor and a MUSIC sensor.

Outline of the TD sensor (S37)(S38)(S39)(S40)

In this machine, a non-contact toner density (TD) sensor, which we also call a mu (μ) sensor, is used for toner density control.

The TD sensor is attached on the lower side of the development unit. Unlike an HST sensor, the board of the TD sensor is exposed. So there is a cover around the sensor to protect it and to maintain a good contact between the sensor and development unit.

The TD sensor measures the permeability of the developer without contacting it, from the outside of the case, and converts the measured value to the toner density.

According to the toner density measured by this sensor, the proper amount of toner is supplied to the developer.

A counter corresponding to the frequency is used as the unit of TD sensor output. Thus, unlike an HST sensor which directly detects Vt, the TD sensor output is converted into Vt for toner supply control.

In the TD sensor, there is an ID chip storing the machine identification information, the running distance information of Development unit and PCU, and other information used by image density control.