- When installing this option, turn OFF the main power and unplug the power cord from the wall socket. If installing without turning OFF the main power, an electric shock or a malfunction may occur.

- This option cannot be used together with the following peripherals:

- Internal Shift Tray SH3080 (D3FV)

- Bridge Unit BU3090 (D3FW)

- Internal Finisher SR 3300 (D3FT)

- Side Tray Type M37 (D3FX)

- Internal Multi-Fold Unit FD3010 (D3FS)

- To use together with the "Punch Unit PU3070", first attach the "Punch Unit PU3070" before installing this option.

Remove the packing tapes and retainers, and then remove the accessories (screws, etc.).

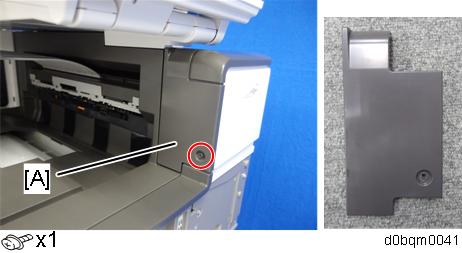

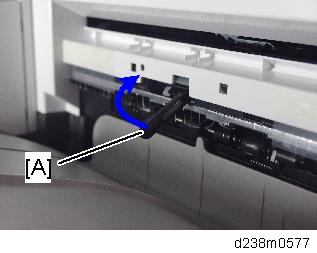

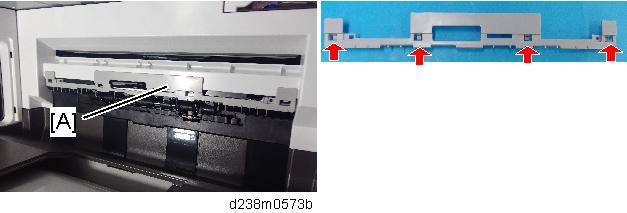

- Remove the paper exit tray [A].

- Remove the paper exit feeler [A].

- Tuck in the lever [A] for detecting when the tray is full.

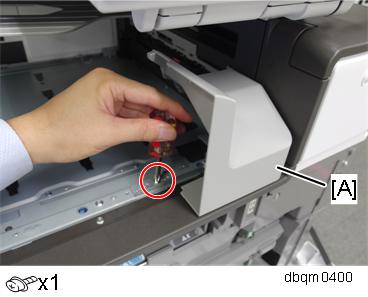

- Open the front cover, and then remove the upper left cover [A].

- Remove the left rear cover [A].

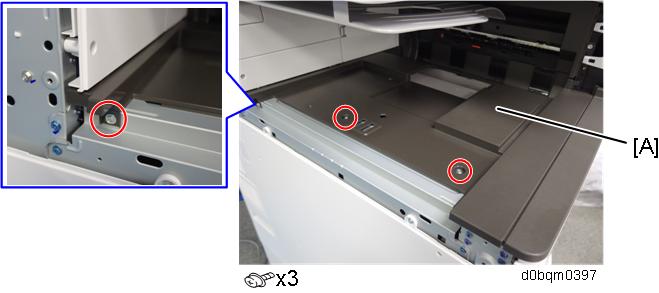

- Remove the paper exit lower cover [A].

- Install a screw removed in step 8.

This protects your fingers from burrs of screw hole.

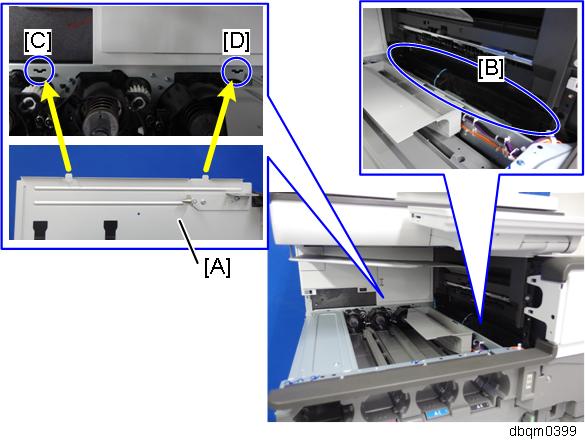

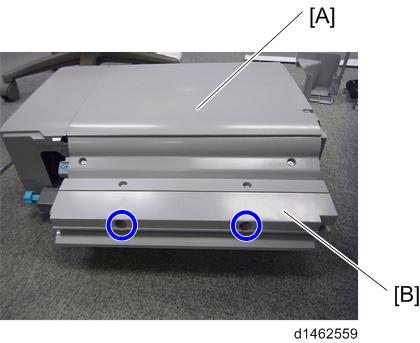

While pressing the bottom plate [A] into the area shown by the blue circle [B], insert it into the slot shown by the blue circles [C] [D].

- The following procedure is the easiest way to set this bottom plate.

1) Slip the bottom plate into the position in the blue circle [B].

2) Insert the bottom plate into the hole in the blue circle [C].

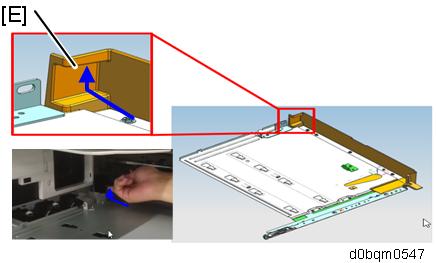

3) Hook the position [E] of the bottom plate with your index finger, and insert the bottom plate into the hole of the blue circle [D] while lifting it.

- The following procedure is the easiest way to set this bottom plate.

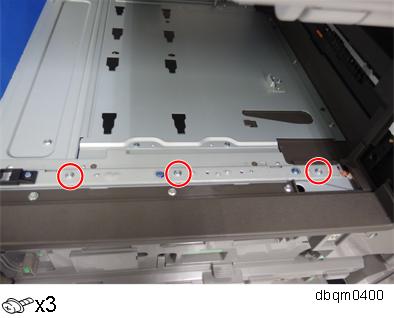

- Attach the bottom plate [A] (M3×6).

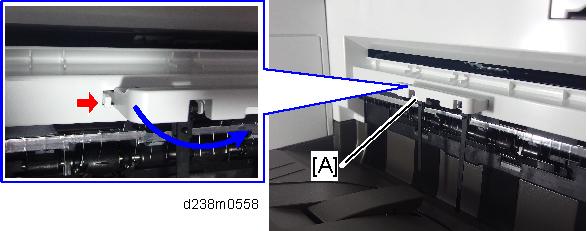

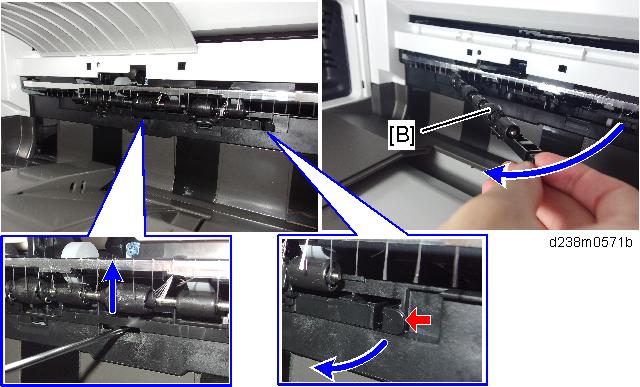

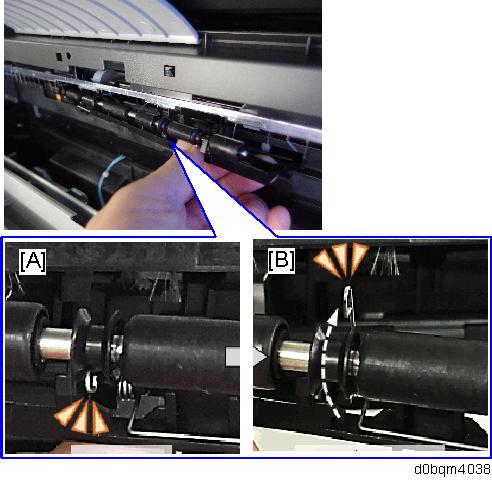

- Remove the driven roller [B] at the machine’s exit tray and attach the supplied driven roller [A].

- Insert a flathead screwdriver into the depression in the center, and then, lifting the driven roller, unlock the part indicated by the red arrow.

- When attaching the driven roller, push its center all the way in until it clicks.

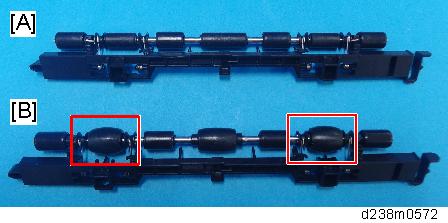

[A]: The supplied driven roller has flat rollers.

[B]: The machine’s standard driven roller has drum-type rollers (as indicated by red frames).

The spring arm on the flat roller might be disconnected due to the vibration or shock. After attaching the roller, perform a visual check whether the state of assembly is normal or not.

[A]: Normal position, [B]: spring arm is disconnected.

Attach the paper support guide [A] (Tab x4).

- Up to this point, the procedure is the same as punch unit installation (for fitting the punch unit, refer to Step 3 and later of the Punch unit installation procedure).

- Slide the finisher front right cover [A] from left to right to attach it (M3x6).

- Attach the entrance guide plate [B] to the finisher [A] (

×2: M3x6).

×2: M3x6).

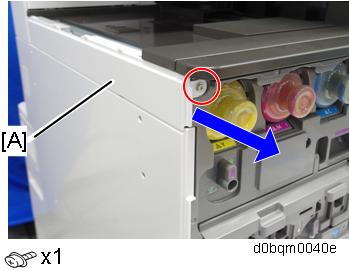

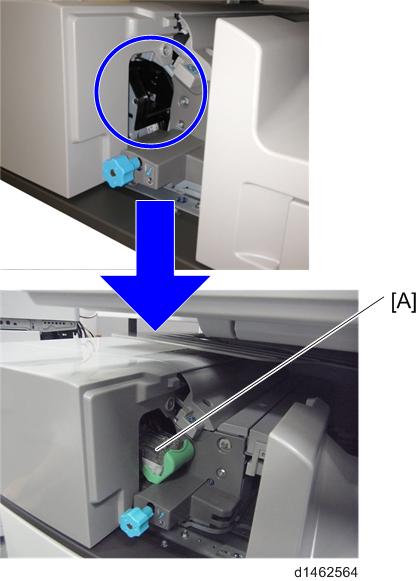

Slide the finisher [A] along the rail of the bottom plate from the left-hand side of the machine to attach it (

×1: M4x6).

×1: M4x6).

- Reattach the left rear cover.

- Insert the upper left cover [A] from the front, and slide it to reattach it.

Use the screw removed in step 5.

Attach the stabilizers.

- Because the weight is biased to the right of the machine if the internal finisher is installed, stabilizers are required on the left side. Because they are included with the finisher, install these stabilizers at the same time as you install the internal finisher.

- Connect the interface cable to the machine.

- Move the stapler unit forward, then set the staple cartridge [A].

- Reinstall the stapler unit, and then turn ON the main power.

- Check that the finisher can be selected at the operation panel, and check the finisher operation. Also when the punch unit is installed, check the punching operation.