The main unit and peripheral devices can be Installed quickly and easily like user maintenance models SP C840DN / SP C842DN (Met-P2).

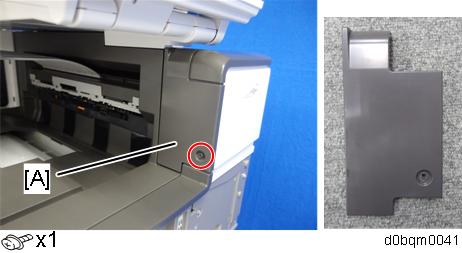

- Image Transfer Front Cover [A]

The image transfer front cover included separately with the previous model is already attached to the main unit.

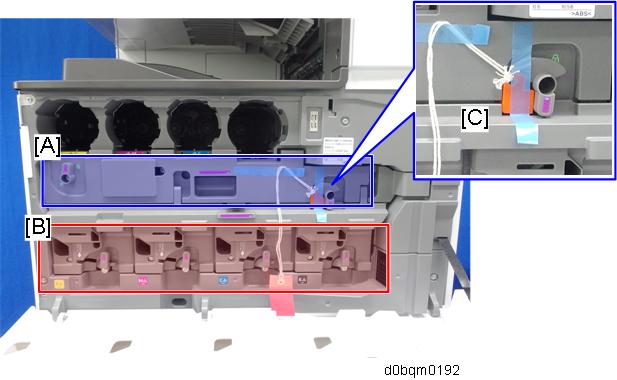

PCDU[B]

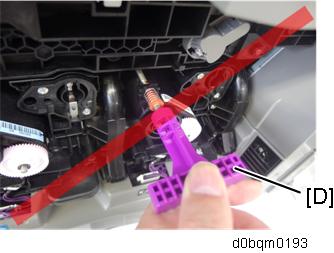

On the previous model, the PCDU seals were wound using the supplied winding lever [D], but this model has been superseded by an auto-wind system.

How PCDU seals are removed

Models CMY K IM C6000/C5500/C4500 Wound automatically when turning on the power IM C3500/C3000 Pulled out by hand Wound automatically when turning on the power IM C2500/C2000 Pulled out by hand

- Spacer [C]

A spacer has been added to secure the ITB contact/separation lever. When shipped from the factory, the image transfer belt and drum are separated, so remove the spacer and raise the ITB contact/separation lever to bring them into contact.

- Proximity Sensor Left Cover

A proximity sensor left cover [A] has been added to the proximity sensor cover.On the previous model, it was necessary to remove the proximity sensor cover when installing the bridge unit and other internal finisher options; but on this model, it is possible to install such options by removing only the proximity sensor left cover.

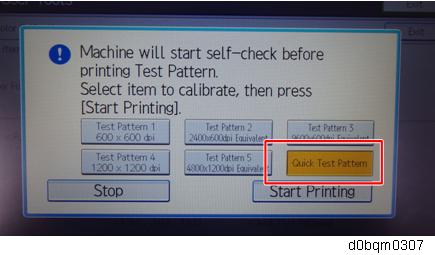

- Auto Color Calibration (ACC) Quick Correction Mode

In response to requests to reduce the time that a service technician takes for adjustment during machine installation, this machine is equipped with Quick Correction mode for Auto Color Calibration (ACC). On the previous model, it was necessary to execute correction at all resolutions (Patterns 1 to 5), but on this model, the correction can be performed simply by executing Quick Test Pattern (Quick Correction Mode) once.