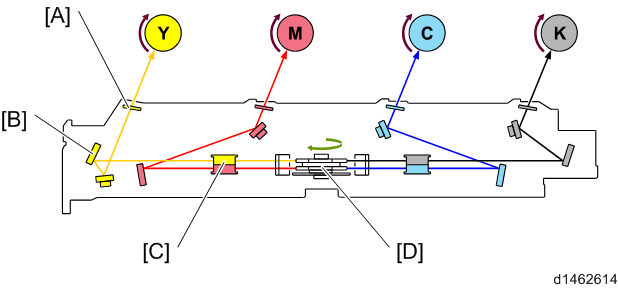

[A]: Dust Shield Glass

[B]: 1st Mirror

[C]: F-theta lens

[D]: Polygon Mirror Motor (M27)

- Mirror, lens

Laser diodes of each color emit light to match the paper transport timing. After passing through the cylinder lens (laser beam width correction), Polygon mirror motor (M27) (main scanning line scan), F-theta lens (dot position correction and optical face tangle error correction), it reaches the drums of each color.

The F-theta lens has a two-stage integrated construction, and 2 color beam correction is performed with one lens. - Polygon mirror motor (M27)

The polygon mirror motor (M27) comprises two (upper and lower) 6-faced mirrors formed in an integral construction (these are combined in one unit).

In this machine, 4 color simultaneous write is performed by the LD irradiating a polygon mirror.

* The rotation speed of the Polygon mirror motor (M27) is controlled by LD/ Polygon mirror motor (M27). - Synchronizing detector board (PCB17)

The single sensor of the synchronizing detector board located beside the K-C color station detects the LD light and controls the 4 colors’ timing according to the timing of incoming beams.This machine has adopted a single-point synchronization system. By positioning the synchronizing detection sensor at the leading edge of the main scan line, the application of colors at the leading edge is synchronized.

- Scanline inclination and automatic adjustment mechanism

The laser optics positioning motor (M23) (M24) (M25) installed on the 2nd mirror adjusts the scan line inclination.

This is done during automatic image position correction.