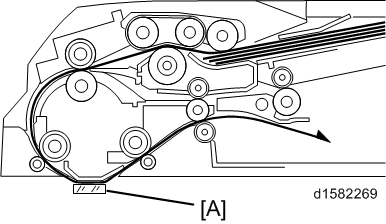

Marks on prints and copies are mostly due to dirt on the DF exposure glass [A], generally caused by adhesive contaminants (such as ball point pen ink and correction fluid).

Compared to non-adhesive contaminants (such as paper fragments and eraser dust), adhesive contaminants are more likely to lead to complaints from customers because of the following:

- Vertical streaks caused by adhesive contaminants are more visible in terms of image quality.

- Unless removed by cleaning, adhesive contaminants continue to produce vertical streaks, while non-adhesive contaminants stop producing streaks after they are dislodged.

- Many adhesive contaminants are difficult to remove by cleaning.

The ARDF/SPDF that is provided with this machine "Machine Features Settings" a system (non-contact scanning) to reduce vertical streaks caused by adhesive contaminants.

Contact scanning: Other ADFs/ARDFs | Non-contact scanning: SPDF/ARFDF for this machine |

|---|---|

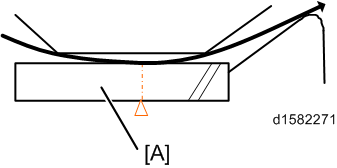

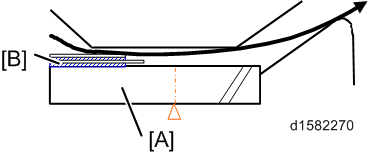

In contact scanning, the whole of the original comes into contact with the DF exposure glass [A] so that non-adhesive contaminants can be removed.  | By means of the Mylar sheet [B], originals are kept slightly above the DF exposure glass [A], preventing adhesive contaminants from adhering to the glass.  |

The SPDF/ARFDF for this machine can be converted from non-contact scanning to contact scanning for users who wish to reduce vertical streaks caused by non-adhesive contaminants.

SP No. | Contact scanning | Non-contact scanning |

|---|---|---|

SP4-688-001 (for ARDF) | 103% | 104% |

SP4-688-002 (for SPDF) | 96% | 101% |

SP4-871-003 (both ARDF and SPDF) | 0.00% | 0.11% |